Our other sites

© Sandvik Mining 2014

Tel +46 (0)26 260000

info.mining@sandvik.com

Loading site...

Scroll down to go deeper

With continued demand from mining companies to ensure safety and increase productivity, Sandvik rock tools are committed to providing the support needed

– through safe products and product information. This hammer complies with the health and safety regulations of the European Union

(= CE machinery directive).

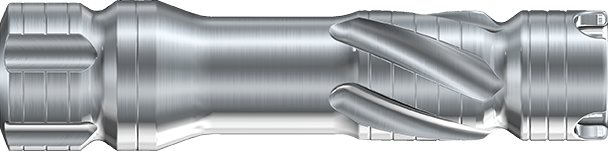

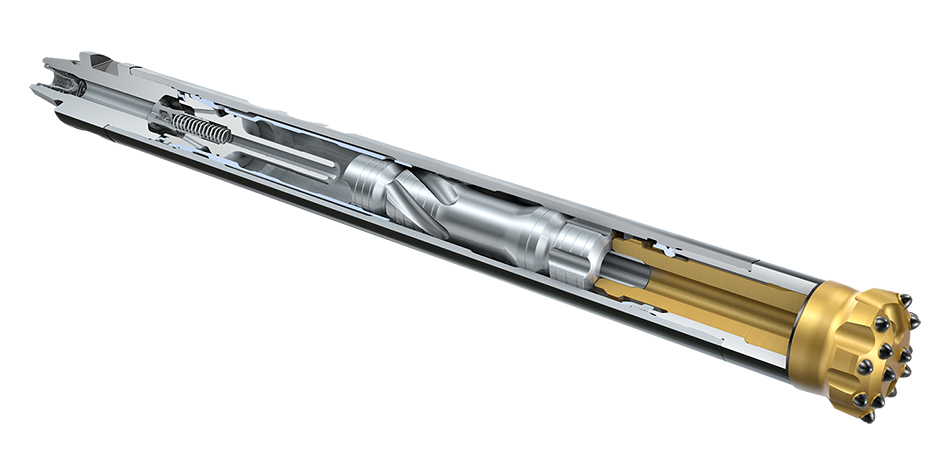

Rising fuel prices have a large economic impact on DTH drilling operations. Lower air consumption in a DTH hammer is key to cutting these costs. The air cycle of the RH460 hammer has been designed to optimize the expansion and compression rate. This results in more power with less air.

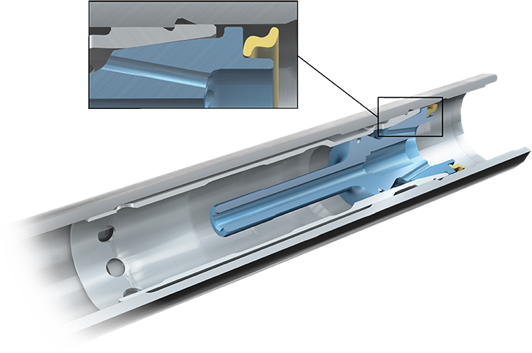

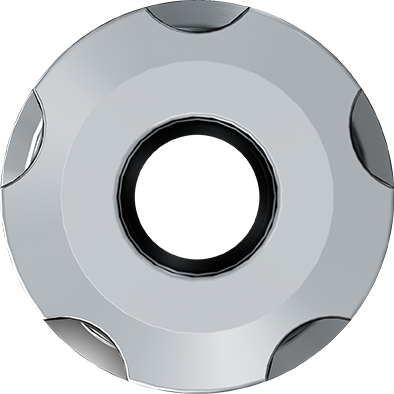

The unique V-lock system used in the RH460 hammer is designed to prevent the movement of the inner cylinder and air distributor. This simple design ensures that no special tools are required for assembly or disassembly. By preventing movement of the components, it reduces galling related failures. The steel make up ring creates a constant make up force, independent of temperature and time compared to other elastic material often used for the same purpose.

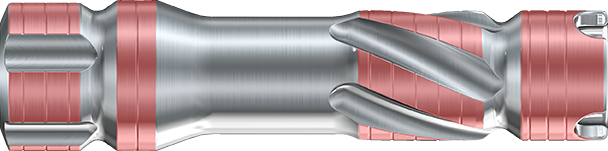

Lubrication plays a crucial role in the service life of the hammer. The oil film creates an airtight seal between the hammer's components, reducing friction wear as well as any heat generated between the moving parts. This reduces the number of failures caused by galling.

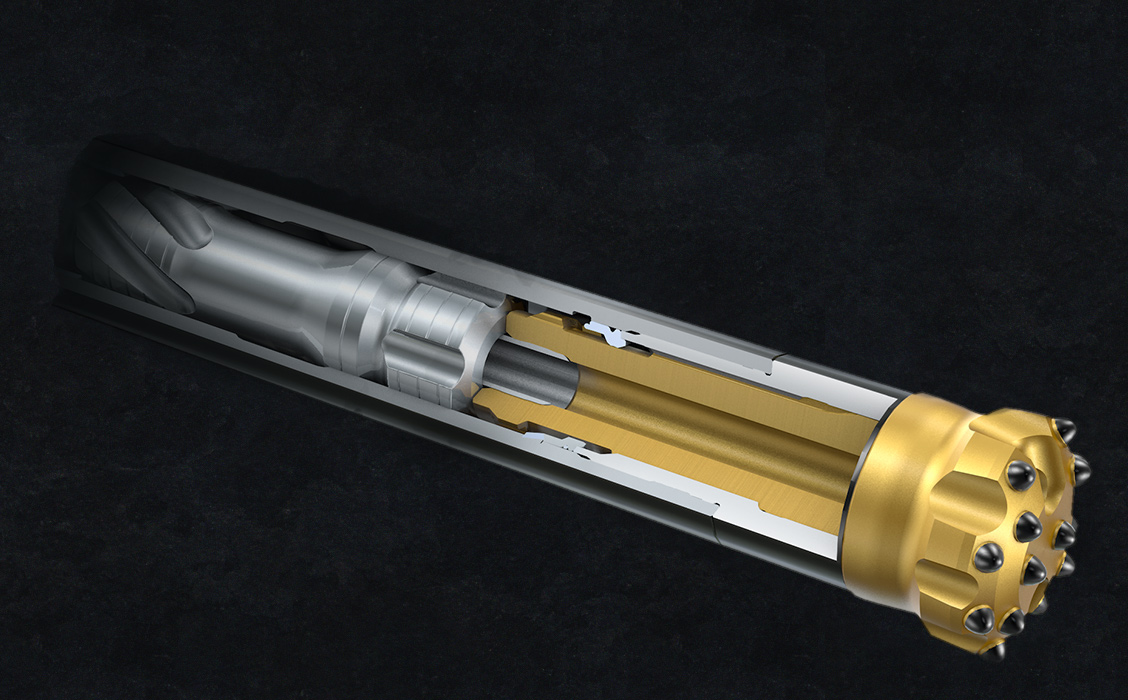

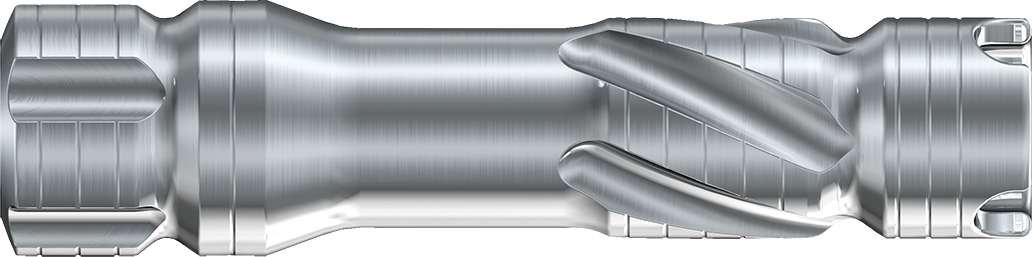

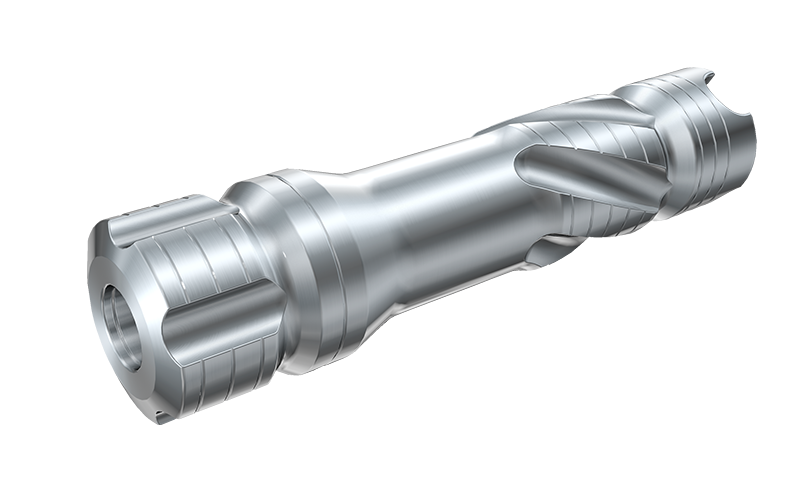

The RH460 hammer is developed with a solid piston and inner cylinder concept. Since the porting is done externally, the piston is free from air channels. The solid piston is design without cross-holes to reduce stress-induced failures.

This, combined with the robust large striking end, increases service life and eliminates premature failures related to fatigue stress.

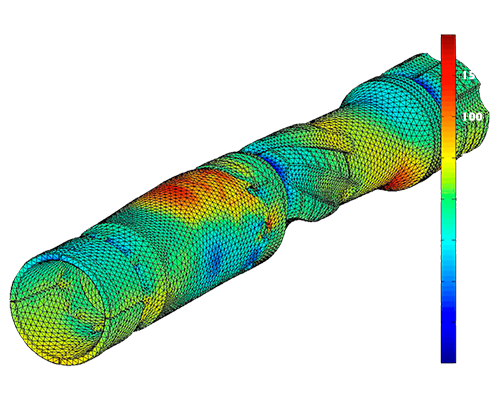

Bending vibrations in the piston lead to high pressure contact between the internal parts during striking mode. This can cause galling and ultimately failure. In the RH460 the piston bearing surface design and location optimizes bearing capabilities and reduces bending vibrations. The RH460 piston is designed to provide reliability and long service life.

Optimized bearing areas Touch the piston to see its optimized bearing areas

The working principle of RH460 ensures that the hammer starts up in any direction. This makes the new RH460 design exceptionally well suited for all surface and underground mining applications.

The new Sandvik RH460 hammer takes DTH drilling to a higher level. It has been developed for superior productivity in variable ground conditions. Higher impact energy lowers air consumption, maximizes productivity and reduces costs. RH460 hammers are designed to use industry standard shanks for greater product flexibility.

The design of the RH460 hammer makes it easy to service and offers a good balance between cost and performance. The V-lock mount system ensures reliability and eliminates the need for shims and special assembly tools. The piston design is optimized with oil grooves in the guide surface to ensure constant and consistent lubrication with dynamic sealing properties. The result is a high performance, cost effective hammer that can be used in almost any ground conditions.

The launch of the Sandvik high pressure hammers, RH460hp, come as a welcome option for those mines working with high pressure rigs. Particularly where focus is on high penetration rate and higher productivity.

These new hammers offer greater air efficiency, reduce fuel consumption, lower operation cost and higher profit (comparing to other hammers at 35bar). Sandvik’s high pressure hammers are designed to operate at higher pressure levels 32-35bar (450-500 psi).

This means to get the full effect of the hammer performance it’s important to run the hammer at 35bar. In addition, the hp hammers share the benefits and values as all RH460 hammers.

The high-pressure hammers, are an ideal match for Sandvik DR500-series rigs

and the company’s new Pantera.

The RH460 family consists of 4 standard size hammers ranging from 4” – 8”.

Sizes 4” and 5” are available in the RH460hp range.

All RH460 hammers are designed to utilize bits with industry standard shanks.

| Size | 4" | 5" | 6" | 8" |

|---|---|---|---|---|

| Type | S | S | S | S |

| - | G | G | G | |

| Shank | DHD 340 QLX 40 |

QL50 | QL60 | QL80 |

| Size | 4" | 5" |

|---|---|---|

| Type | S | - |

| - | G | |

| Shank | QLX 40 | QL50 |

Productivity and high penetration –

that’s what the Sandvik RH460 and RH460hp series of DTH hammers deliver.